Inventory Management System

An Inventory Management System (IMS) is a software-based solution that helps businesses efficiently track, manage, and control their inventory levels. It automates the process of ordering, stocking, and selling products, optimizing stock levels while reducing carrying costs and stockouts. IMS allows businesses to monitor inventory in real-time, track product movement, and generate reports for analysis. Key features include barcode scanning, serial number tracking, batch tracking, and integration with other systems like Point of Sale (POS) and accounting software. By providing accurate inventory data and streamlining operations, IMS improves efficiency, reduces errors, and enhances overall business performance.

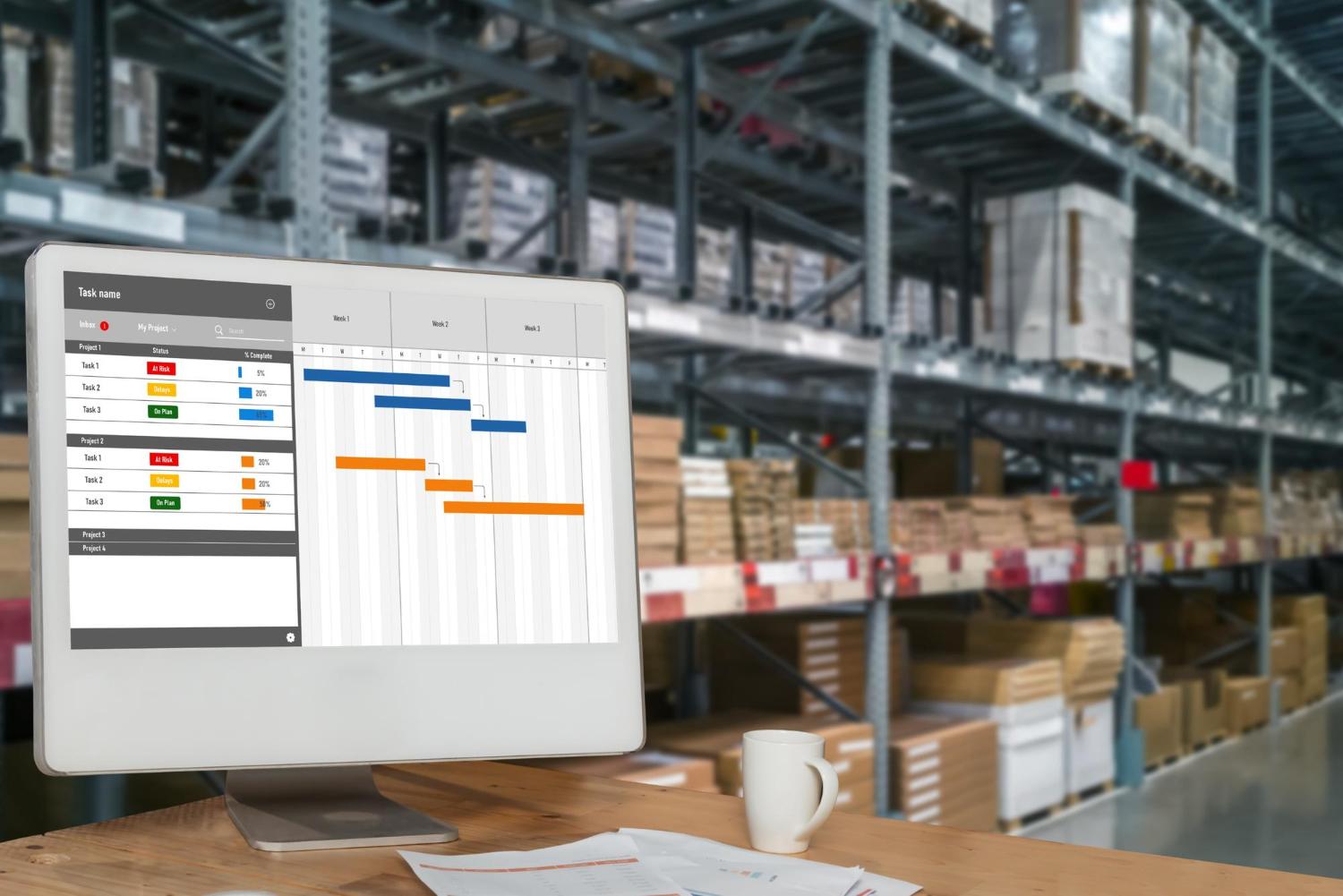

Warehouse Management System (WMS)

Streamline your warehouse operations and optimize inventory management with our comprehensive Warehouse Management System (WMS). Our WMS provides robust features to enhance:

- Inventory Tracking: Gain real-time visibility into your stock levels, ensuring accurate inventory management.

- Order Fulfilment: Efficiently manage order processing, from picking and packing to shipping, to meet customer demands swiftly.

- Enhanced Accuracy: Reduce errors with automated processes and improved tracking, leading to better overall accuracy in your operations.

- Increased Efficiency: Optimize workflows and resource allocation to enhance productivity across your supply chain.

- Reporting and Analytics: Access detailed insights and analytics to make informed decisions and continuously improve your warehouse performance.

With our WMS, you can enhance accuracy, visibility, and efficiency, ultimately driving success throughout your supply chain.

TAT (Vehicle Turnaround Time) Using RFID

Optimize your logistics operations with our advanced RFID and barcode solutions to accurately calculate Vehicle Turnaround Time (TAT) within your factory or plant premises. Our system allows you to:

- Track Time Efficiently: Monitor the duration each vehicle spends on-site, providing insights into operational efficiency.

- Inbound/Outbound Timeline Analysis: Calculate the time taken for vehicles to enter and exit each bay, helping to identify bottlenecks and streamline processes.

- Enhance Logistics Efficiency: Use real-time data to improve the logistics and supply chain workflow, leading to reduced delays and increased throughput.

- Data-Driven Insights: Leverage comprehensive reports to make informed decisions that optimize vehicle management and resource allocation.

With our RFID and barcode technology, you can significantly improve the efficiency of your logistics operations and enhance overall supply chain performance.

What is IoT?

The Internet of things describes physical objects with sensors, processing ability, software, and other technologies that connect and exchange data with other devices and systems over the Internet or other communications networks

Automatic Goods Receipt Note

An Automatic Goods Receipt Note (GRN) is a digital document generated by a system to confirm the receipt of goods into a warehouse or inventory. It automates the process of updating inventory records upon the arrival of shipments from suppliers. When goods are received, the system compares the received quantity with the purchase order and generates a GRN with details such as item descriptions, quantities, and dates. This digital record improves accuracy, reduces manual data entry errors, and speeds up the reconciliation process. Automatic GRNs streamline inventory management, provide real-time visibility into stock levels, and facilitate seamless integration with other supply chain systems.

Production Entry and Reporting System

A Production Entry and Reporting System is a software solution used in manufacturing to track and manage production activities. It allows operators to log production data such as quantities produced, downtime, scrap, and machine performance. The system provides real-time visibility into production status, enabling managers to monitor progress and make informed decisions. It generates detailed reports on production output, efficiency, and quality, facilitating performance analysis and improvement initiatives. Production Entry and Reporting Systems improve operational efficiency, reduce manual data entry errors, and enhance overall production management. They are essential tools for optimising manufacturing processes and achieving production targets.

Online Statistical Process Control

Online Statistical Process Control (SPC) is a methodology used in manufacturing to monitor and control processes in real-time. It involves collecting data from production processes continuously and analysing it to detect variations and deviations from target values. SPC software applies statistical techniques to determine if a process is stable and within control limits. It alerts operators to take corrective actions if anomalies are detected, preventing defects and ensuring consistent product quality. Online SPC provides insights into process performance, helps identify root causes of issues, and enables proactive decision-making. It is a key tool for achieving process optimization, reducing waste, and improving overall production efficiency.

Tools Management System

A Tools Management System is a software solution used to efficiently track, manage, and maintain tools and equipment in various industries. It provides a centralised platform to catalogue all tools, recording details such as location, usage history, maintenance schedules, and calibration dates. The system automates tool checkout and return processes, reducing loss and improving accountability. It sends alerts for scheduled maintenance and calibration, ensuring tools are in optimal condition. Tools Management Systems enhance tool availability, reduce downtime, and improve productivity by ensuring the right tools are available when needed. They also provide valuable insights into tool usage patterns for better resource planning.

Visitor Management System

A Visitor Management System (VMS) is a software solution used to streamline and enhance the visitor check-in and check-out process at facilities. It replaces traditional paper-based visitor logs with electronic systems, improving security and efficiency. VMS allows for pre-registration of visitors, captures visitor information, prints visitor badges, and tracks visitor movements within the premises. It can also integrate with access control systems to grant temporary access to visitors. VMS enhances security by identifying and screening visitors, improves the visitor experience with smoother check-in processes, and provides organisations with accurate visitor data for reporting and auditing purposes.

Contract / Casual Labor Management System

A Contract / Casual Labor Management System is a software solution used to efficiently manage temporary or on-demand workforce in organisations. It automates the process of hiring, scheduling, tracking, and paying contract or casual labourers. The system maintains a database of available workers, their skills, qualifications, and availability. It facilitates the assignment of tasks, tracks work hours, and calculates wages or payments based on completed work. Contract / Casual Labor Management Systems streamline workforce management, ensure compliance with labour laws, and provide real-time visibility into labour costs and productivity. They improve operational efficiency by simplifying the management of temporary workforce and reducing administrative burden.

Suggestion Management System / Improvement Ideas

A Suggestion Management System (SMS) is a platform that enables employees to submit, track, and implement improvement ideas or suggestions for the organisation. It encourages a culture of innovation and continuous improvement by providing a structured process for employees to share their insights. The system allows for the submission of ideas, reviews by designated stakeholders, and tracks the progress of implementation. SMS helps organisations harness the collective intelligence of their workforce, leading to increased employee engagement, productivity, and efficiency. It fosters a sense of ownership among employees and promotes a proactive approach to problem-solving and process optimization. SMS is a valuable tool for driving organisational growth and success through employee-driven innovation.